In order to overcome the shortcomings of unsaturated diene rubber, especially natural rubber CV vulcanization system in rubber production, in 1977, S. Woff used the ratio of Si69 tetrasulfide in the amount of substances such as accelerators. Under the condition, the cross-linking density of the vulcanized rubber is in a dynamic constant state, the reversion of the vulcanization is minimized or the reversion of the vulcanization is eliminated, and the vulcanization system is called an equilibrium vulcanization system. The system has better flatness of vulcanization, stable crosslink density, excellent heat aging resistance and fatigue resistance in a long vulcanization cycle, and is particularly suitable for vulcanization of large and thick products.

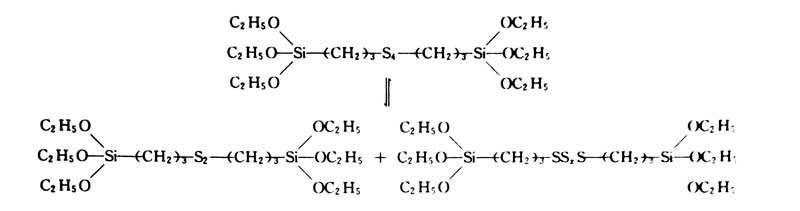

Si69 is a vulcanizing agent with coupling. At high temperature, it is unevenly cracked into bis(triethoxysilylpropyl) disulfide and bis(triethoxysilylpropyl) polysulfide. The mixture is as shown.

Si69 acts as a sulfur donor in the vulcanization reaction of rubber to form a rubber/rubber bridge. The chemical structure of the crosslinks formed is related to the type of accelerator. In the NR/S169/CZ (DM) vulcanization system, it is mainly formed. Disulfide and polysulfide crosslinks; in the NR/Si69/TMTD system, a network structure dominated by monosulfide crosslinks is formed.

Since the crosslinking rate constant of the sulfurized system of Si69 is lower than that of the corresponding sulfur vulcanization system, the rate of positive vulcanization of Si69 is slower than that of sulfur vulcanization, so in the vulcanization system of the S/Si69/accelerator equimolar ratio combination, because The reduction of the crosslink density caused by the reversion of sulfur can be compensated by the new polysulfide or disulfide crosslinks formed by Si69, so that the crosslink density remains unchanged during the vulcanization process, and the physical properties of the vulcanizate are stabilized. status.

In the silica-filled compound, Si69 is coupled with silica in addition to the cross-linking reaction. The filler-rubber bond is produced to further improve the physical properties and process properties of the compound.

The order of anti-reversion ability of various accelerators in natural rubber is

DM>N()BS>TMTD>DZ>CZ>D

In order to improve the disadvantages of NR reversion, in addition to Si69, the rubber industry also uses other anti-reversion agents, such as cyclohexane-1,6-dithiosulfate dihydrate (Duralink HTS), 1,3- Bis(Limonimidomethyl)benzene (Perkalink-900) and the like.